How to automate lubrication in Intralogistics – and prove the ROI in warehouses and DCs

In 15+ hour operation warehouses, manual greasing is noisy, inconsistent, sometimes dangerous, and hard to schedule. It leads to higher wear, energy consumption, and safety risks. Automatic single-point lubricators keep bearings, chains, and guides in the “optimum” zone. Result: cutting wear and unplanned stops while freeing technicians for higher-value work.

In this guide, we’ll show you how to implement automation step by step – and how to build a solid ROI case based on energy, labor, and uptime.

Step-by-step: from manual to automatic lubrication in Intralogistics

1) Map all assets and points

Walk the line and tag:

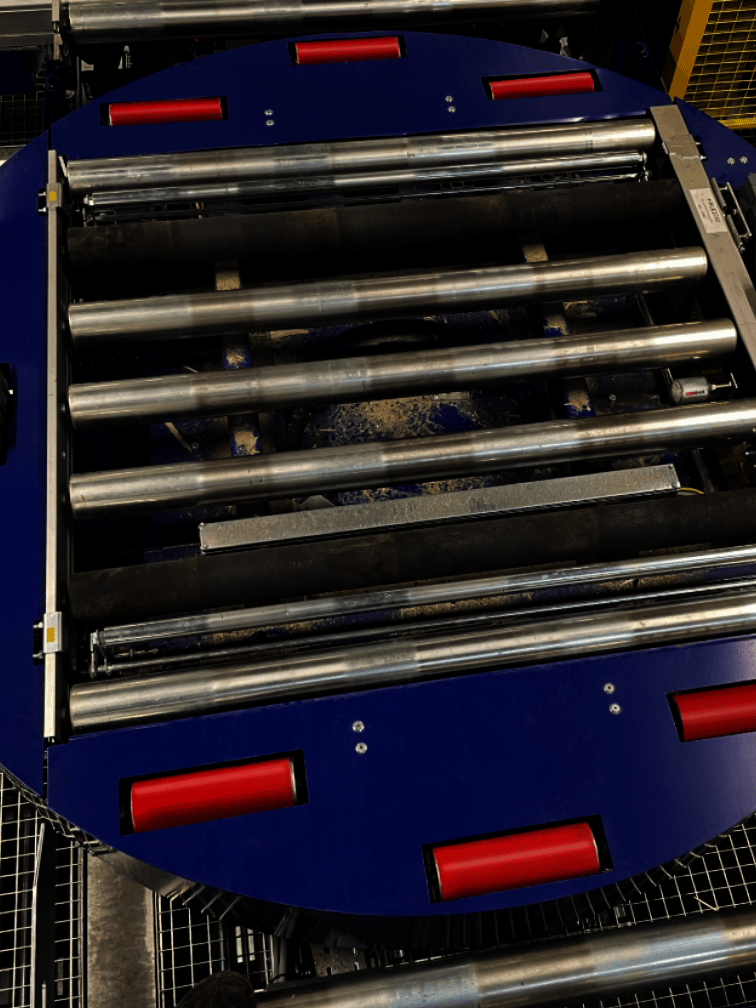

AS/RS rails & mast chains; conveyor rollers & chains; spiral conveyors; robot joints/ball screws; vertical lifts/carousels; forklifts (load chains, wheel bearings, hydraulics). Prioritize high-load, high-temperature, or hard-to-reach points.

2) Set target intervals & lubricant quantity

Use OEM specs and duty cycle. Aim for continuous micro-dosing (not monthly bursts) to minimize friction, noise, and power draw. Consistent lubrication extends component life by up to 30%.

3) Select dispenser size & runtime

Choose 15/30/60/125/250 ml and set runtime (e.g., 1–12 months). Match consumption to avoid over- or under-lubrication; simalube provides steady dosing across the interval.

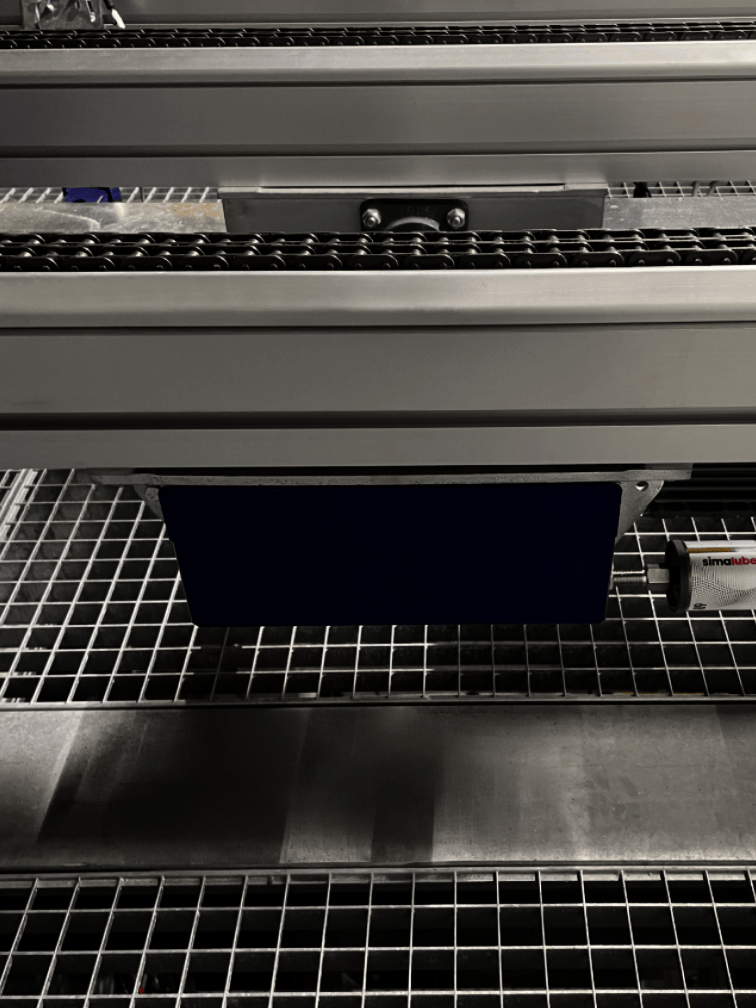

4) Install and label

Mount the dispenser, route tubing if remote mounting improves safety (not longer than 50cm), and label with start date, grease type, and exchange date. Automating removes risky interventions on running equipment and improves occupational safety.

5) Verify with vibration/condition checks

Post-install, log vibration/temperature. Users report clearly harmonized vibration profiles when switching from sprays to automatic dosing.

6) Standardize Preventive Maintenance and replenish cycles

Swap dispensers at planned intervals, and track consumption vs. failures. Result: fewer breakdowns, smoother flow, quieter operation.

Proven ROI from a Swiss Distribution Center

A leading logistics site in Switzerland automated lubrication across conveyors, motors, and lifts – here’s what they achieved:

- Energy savings: A consistent reduction of ~0.2 A per motor thanks to continuous micro-dosing → Substantial energy cost reduction across large fleets.

- Labor efficiency: Same site cut from 600 to ~112 hours/year of lubrication by eliminating monthly/biannual spray rounds.

- Materials savings: From 11,160 spray cans/year to right-sized dispensers; less waste and cleaner lines.

- Total cost saving: USD 173,647/year saved (energy + materials/labor) across ~1,116 motors and ~3,000 conveyors—not including the cost of downtime (USD 72,666/hour).

- Longer Component life: Up to 30% longer for bearings, chains, guides with consistent lubrication.

- Lower Maintenance costs: Up to 25% lower with predictive maintenance + automatic lubrication; availability up to +15%.

Why it matters for your bottom line

Automated single-point lubrication doesn’t just cut noise and friction — it delivers measurable, recurring savings across energy, labor, materials, and machine life.

Checklist: “Are you ready to automate?”

- All lubrication points and duty cycles are mapped

- Grease type is selected

- Safe access or remote mounting is planned

- CMMS tasks and labels are prepared.

Calculate your saving potential and get a point-by-point plan for your site: Request your intralogistics lubrication blueprint (audit + sizing + ROI).