From Lunchtime Run to Maintenance Masterclass: How a Jog Turned Into a Customer Project

Success Story from the Wangen an der Aare Pump Station: Precision, Efficiency, and Partnership with simatec

At the Mülifeld pump station in Wangen an der Aare, a major challenge was on the horizon: After an impressive 50 years of operation, a spherical roller bearing in a screw pump had to be replaced. A task where experience, precision, and professional tools are essential — and exactly where simatec stepped in.

Customer on installation day:

"Just 15 minutes after your jog, you already contacted us about the bearing."

That spontaneous encounter became a true opportunity — thanks to a prompt, professional follow-up. From the initial contact to the successful installation, one thing became clear: Proactive support and proximity to the customer pay off.

simatec in Action: Tools That Deliver Results

For the installation of the new spherical roller bearing (SKF 24148 CC/W33, 79.2 kg), simatec relied on its proven technologies:

World of Maintenance App – Full Digital Control

The heating process was monitored and controlled via the World of Maintenance App. The technician managed the entire operation through their smartphone — efficient, mobile, and fully documented.

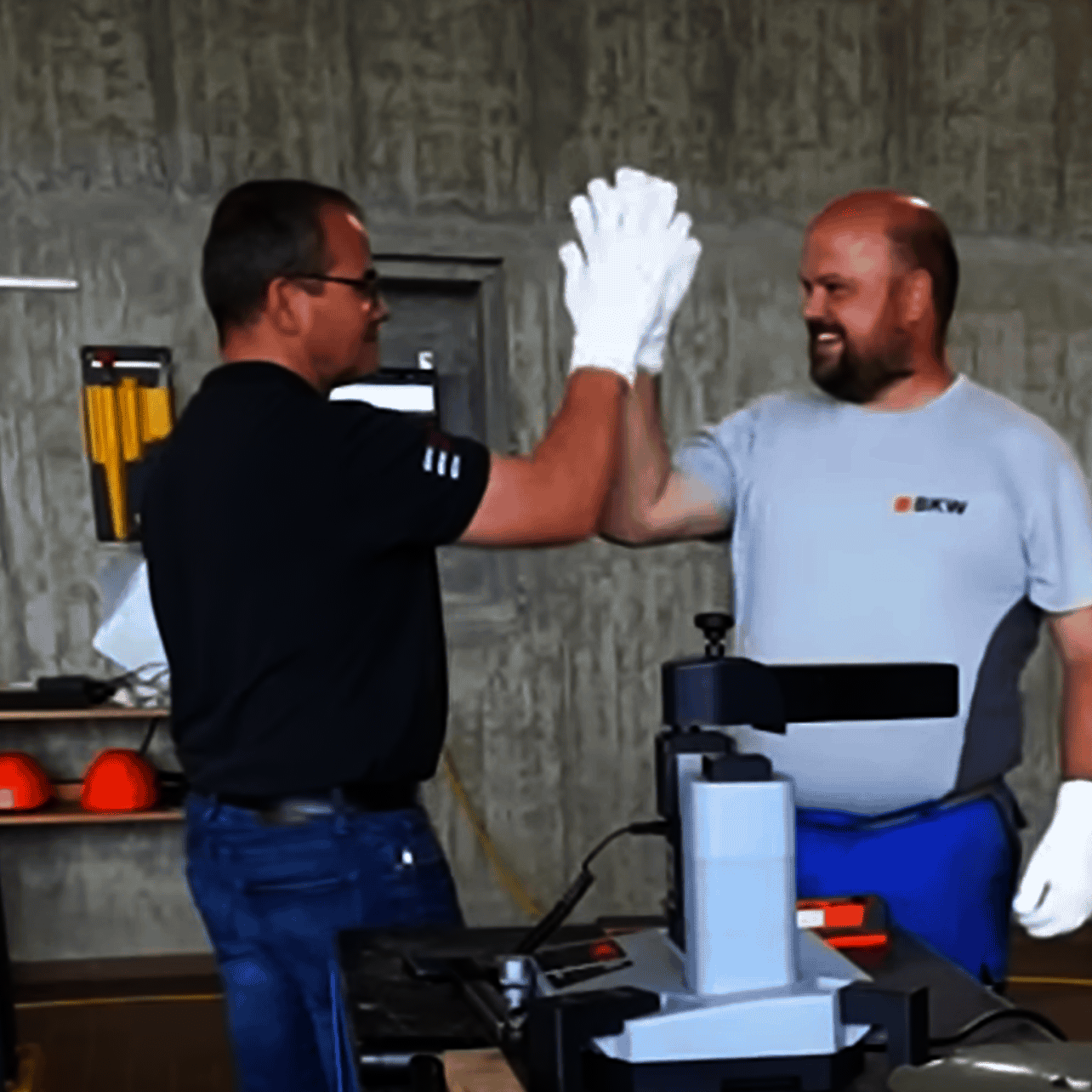

Hands-On Collaboration: When Technology Meets Practice

A highlight of the day was the on-site training during the installation. The customer was actively involved — experiencing first-hand how easy, safe, and fast a bearing can be installed using the right tools. Close coordination with the simatec team ensured a smooth process and maximum learning effect.

From Coincidence to Customer Success

This story clearly illustrates the power of flexibility, customer proximity, and fast response times. What began as a chance encounter during a jog evolved into a textbook example of proactive service.

“Simple, fast, safe and professional installation — the customer was absolutely happy.”

Watch the Video

The Perfect Match: IH 125 + BHT

Key Benefits for Users

- Time savings & process reliability: Even heating with temperature automation and data recording reduces rework

- Safe handling: Ergonomic lifting, guiding and positioning of heavy bearings – horizontally or vertically

- Component protection: No open flames, no oil bath – induction heating acts directly on the workpiece while the device stays cool

- Traceability & training: Full control and documentation via the app