Redefining Maintenance Speed

In the fast-paced world of industrial maintenance, time isn't just money: it’s the difference between a smooth operation and a costly shutdown. We recently put our simatec tools to the ultimate test: a high-speed "Maintenance Parcours."

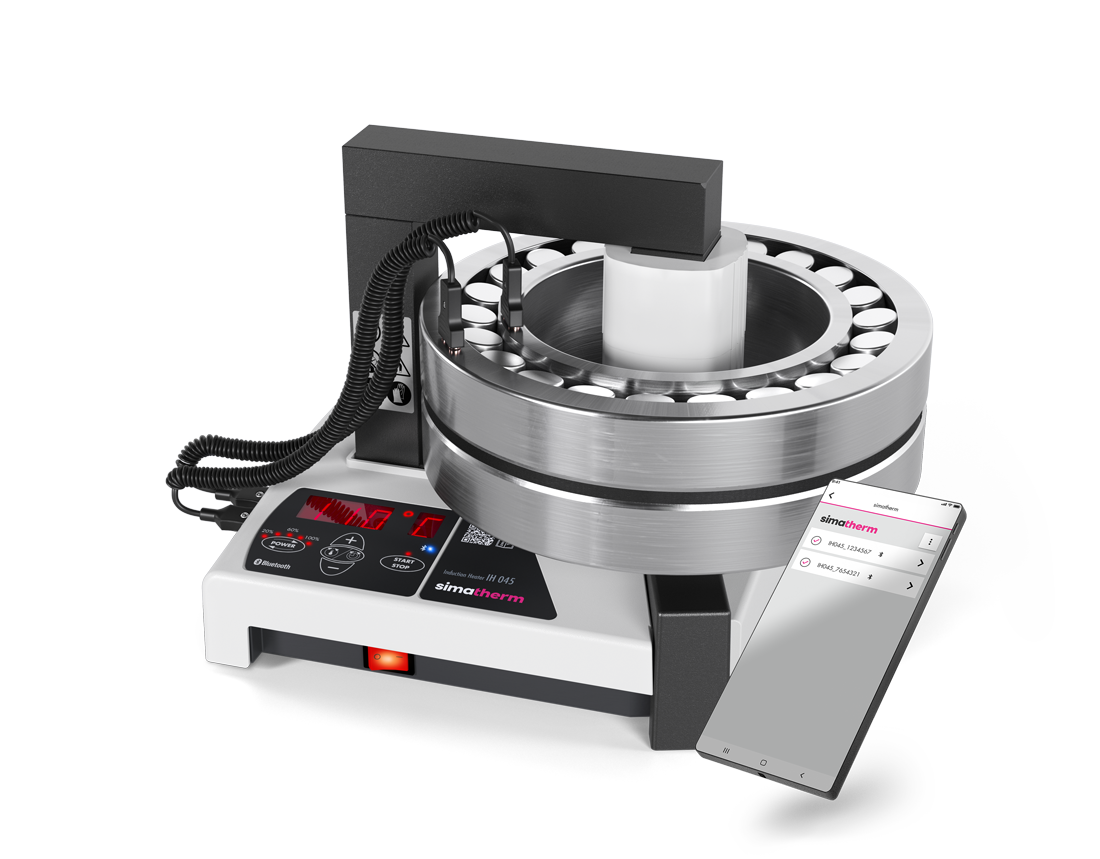

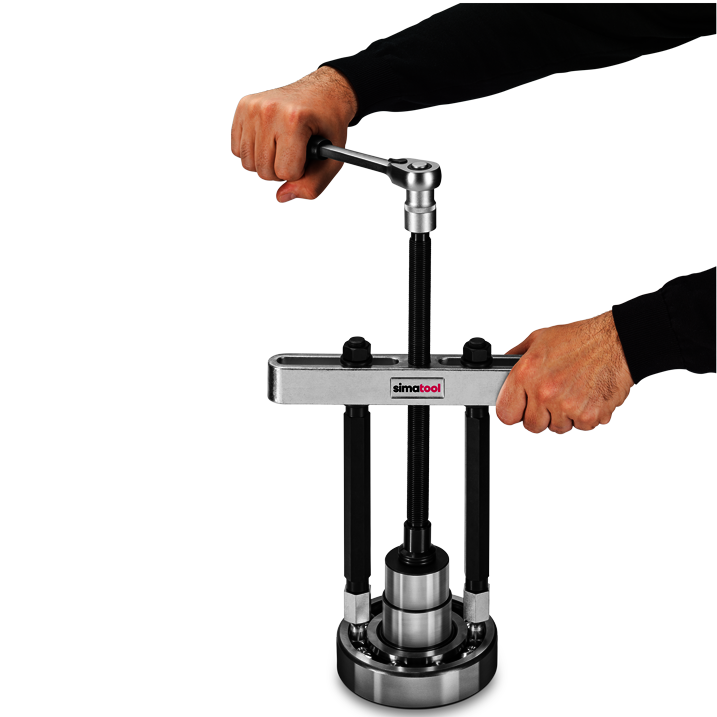

The Challenge: Complete five essential bearing handling tasks using five different tools.

The Result: A full circuit finished in just 5 minutes and 15 seconds.

Here is how we optimized the workflow:

Why It Matters

This circuit proved that when you have the right tool for every specific stage of the bearing life cycle, you don't just work harder, you work smarter. By reducing a multi-stage maintenance task to just over five minutes, simatec tools allow your team to:

- Minimize Downtime: Get machinery back running faster.

- Increase Safety: Proper tools mean fewer slips and accidents.

- Extend Asset Life: Precision handling prevents premature bearing failure.

Is your workshop running at this speed? Explore the full range of simatec maintenance tools and turn your hours of maintenance into minutes.