simalube usage in sewage treatment plants

During the complex cleaning processes which take place in wastewater and sewage treatment plants, mechanical parts such as chains, bearings and guides come into contact with water containing waste, phosphates and acidic substances. The weather also has a major impact on equipment and facilities. Without regular lubrication, the parts will wear out faster, causing the equipment to stop working properly and necessitating expensive repair work. For this reason, continual lubrication is vital.

Lubrication points

Challenges

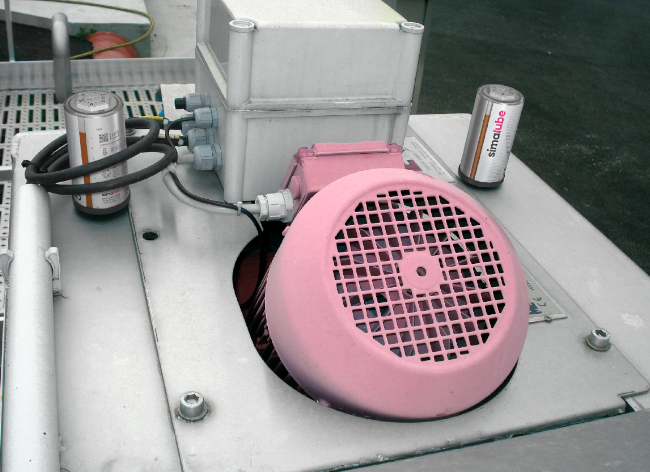

- Outdoor applications

- Temperature fluctuations

- Applications partly in hazardous areas (Ex areas)

Solution

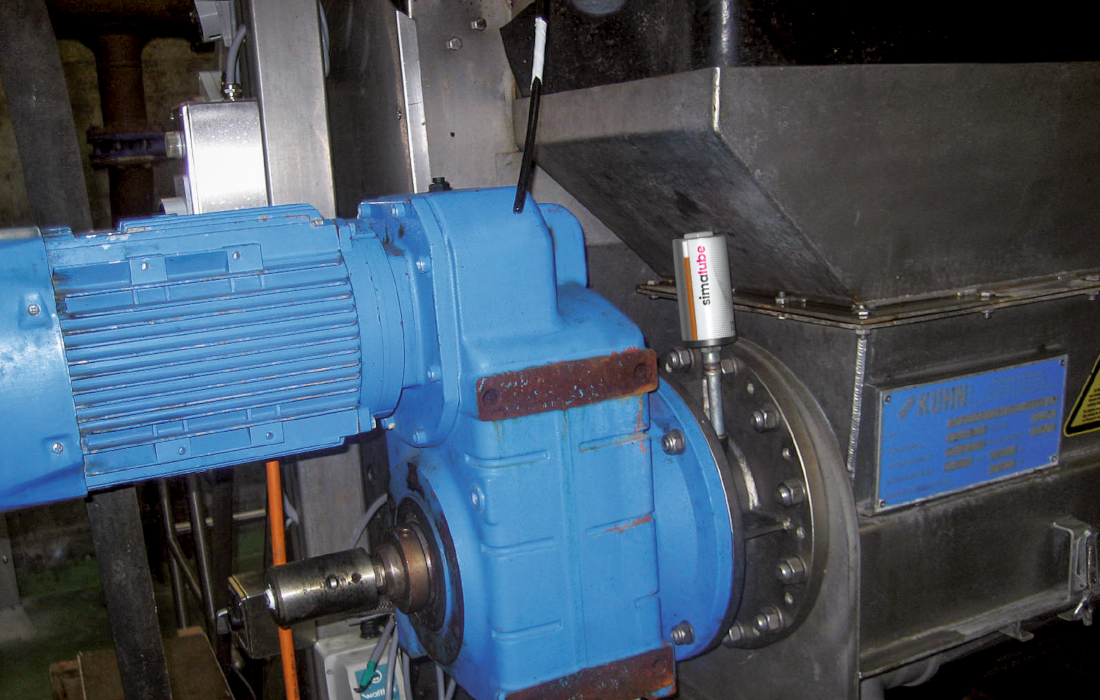

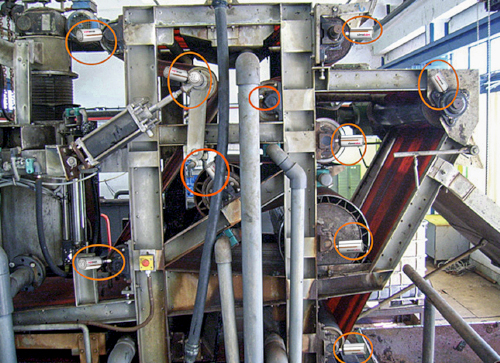

- simalube lubricator

- IMPULSE connect: Digital monitoring and configuration of lubrication points via Bluetooth®. The lubrication points can be monitored from a distance of 20 m. The device can be used to increase the pressure up to 10 bar.

Areas of application and advantages

simalube applications in wastewater and sewage treatment plants

- Clearing devices in primary and secondary clarifiers

- Sludge dewatering and sludge storage

- Sand and grease filters

- Agitators and rabble rake devices

- Screening plants

- Presses

- Slide valves

- Pump stations

- Digestion tanks

Further benefits

- Reliability: Once installed, the lubrication points are reliably lubricated and never forgotten

- The hermetically sealed system prevents contamination by dust and debris (IP68)

- Reduction of service requirements and maintenance costs: Manual lubrication is no longer necessary meaning fewer disruptions and a huge saving of time

- Longer service life of machines thanks to continuous and accurate lubrication

- Flexibility: The running time is adjustable from 1–12 months

- No need to shut down the machines during maintenance

- Approved in all Ex zones

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.