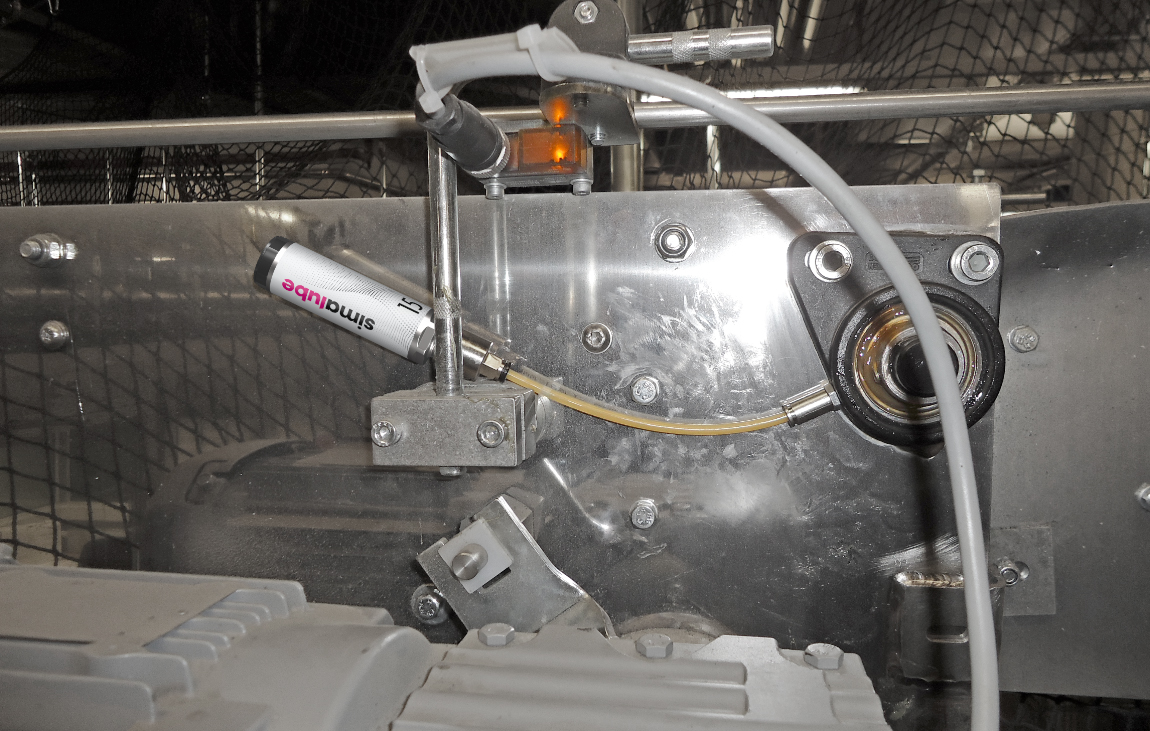

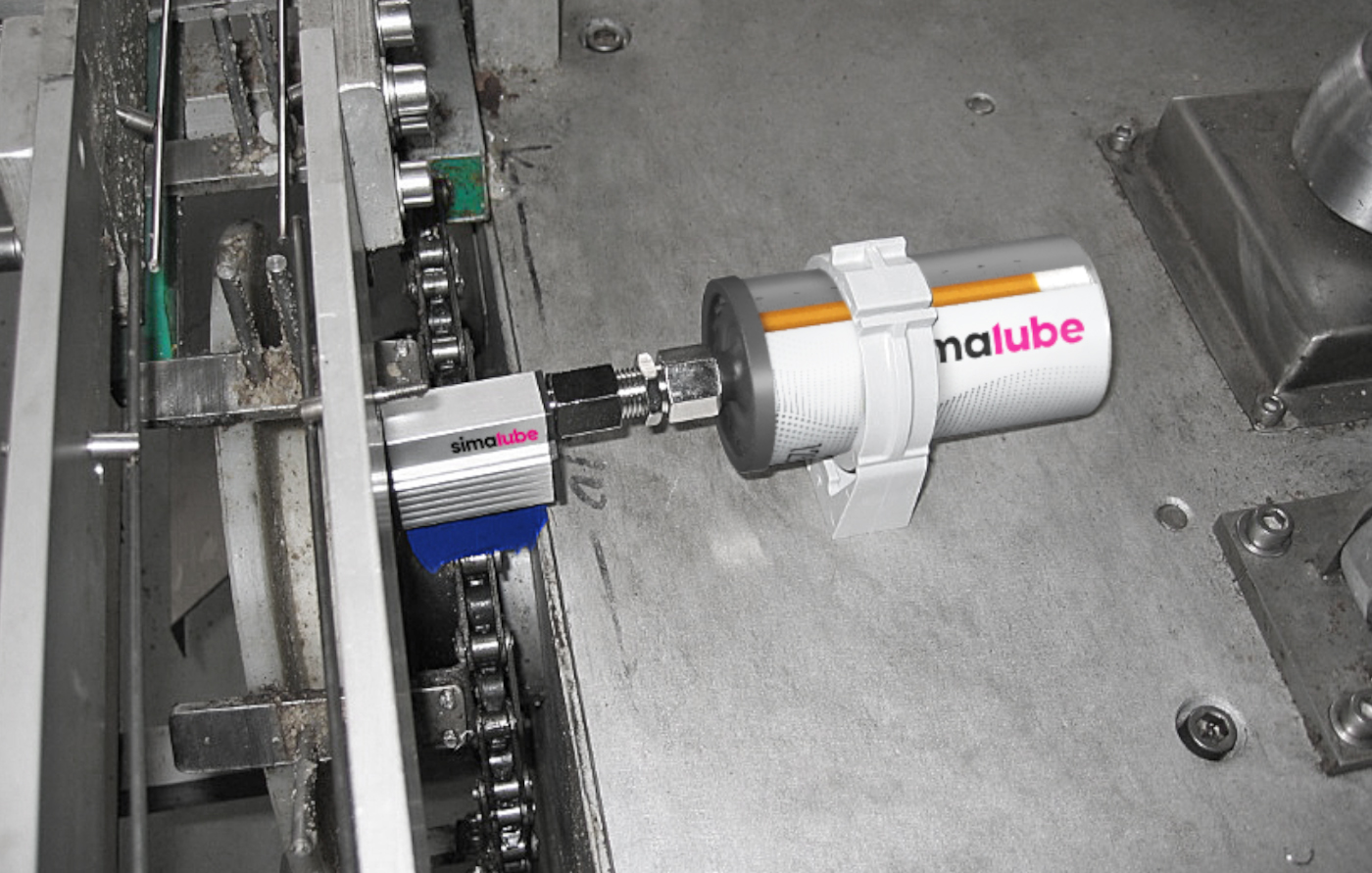

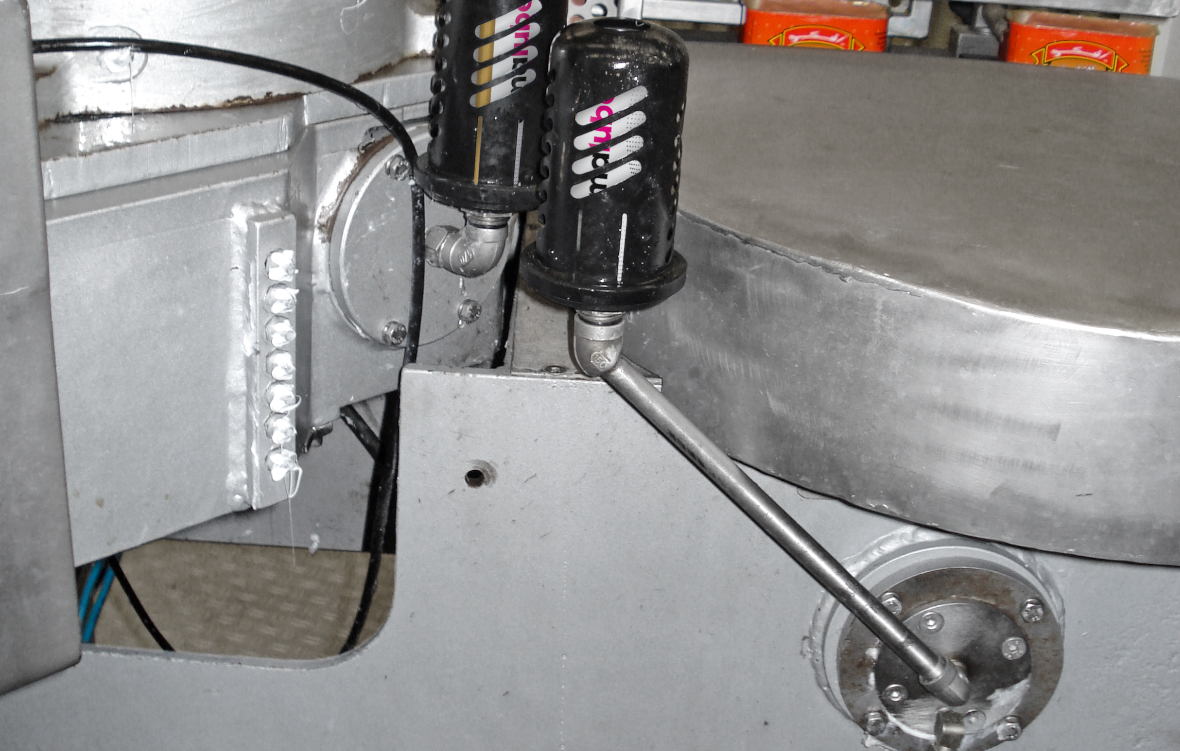

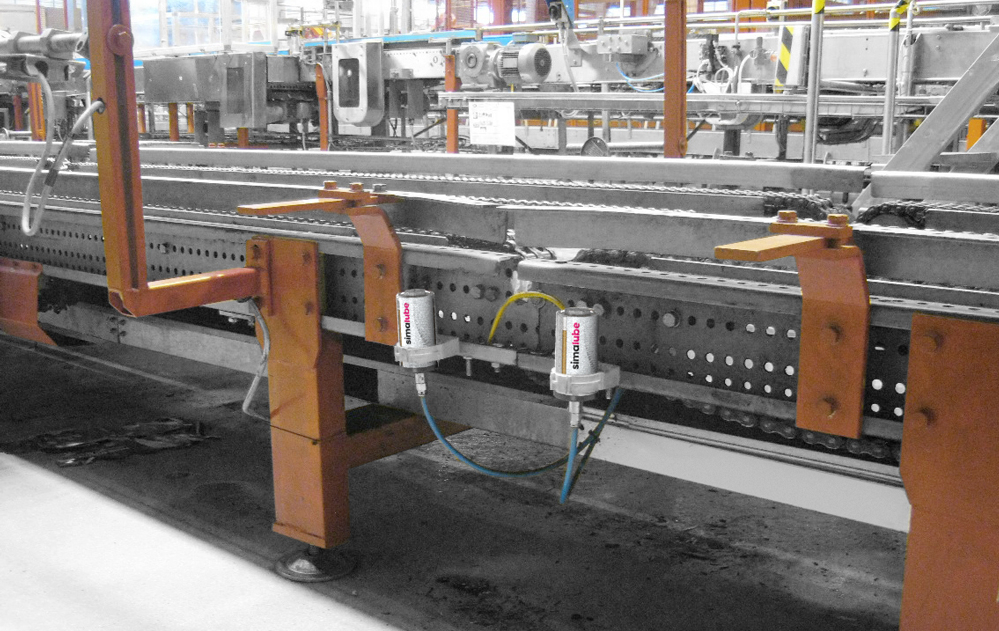

simalube in use in the beverage and food industry

Machines and systems in the food industry must function perfectly even under extreme conditions of use. Dampness, contamination, high temperatures and high relative humidity stress the parts of the system and have a considerable adverse effect on the working life of bearings and chains. In most cases in the food industry, this involves mass production systems, where any downtime means high production losses. Even in modern beverage plants, chain or conveyor systems are in operation 24 hours a day and continuous lubrication extends their reliability and service life enormously.

Lubrication points

Challenges

- High demands on the durability of the products

- The use of approved special lubricants requires a flexible product

- Usage partly in dust explosion hazardous areas (ATEX)

Solution

- simalube with H1 approved lubricants for the food industry

- Special accessories for the food industry

- simalube lubricant dispensers are approved in all ATEX areas

Areas of application and advantages

Typical installations

- Conveyor belts

- Palletizing systems

- Presses

- Washing machines

- Packaging machines

- Processing machines

- Ventilators / Fans

- Conveyor systems

Typical applications

- Bearings

- Chains

- Guides

- Gears

Further benefits

- Increased operational safety

- Reduced downtime

- Constant supply of hard to reach lubrication points

- Less time spent on maintenance

- Reduction of wear and longer life of the components

simalube applications in the food industry

- Preparation processes (peeling, grinding, pressing, cutting machines)

- Processing operations (washing units, cooling and freezing units)

- Filling and loading processes (conveyor systems, slicers, filling systems)

- Packing machines (packing, shrink-wrapping labelling)

- Palletizers

simalube applications in the beverage industry

- Filling machines

- Washing machines

- Belt conveyors

- Packaging and shrink-wrap machines

- Presses

- Refrigeration and freezer units

- Label machines

- Palletiser

- Air conditioners (facility management)

Benefits from automatic lubrication with simalube

- Reduction in servicing and maintenance: no more lubrication by hand, this results in enormous savings of time costs

- It is not necessary to switch the machines off while they are being serviced

- Longer service life of machines thanks to continuous and precise lubrication

- Flexibility: The running time is adjustable from 1–12 months

- Only one type of lubricator is needed per application. This allows a reduction of storage costs

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.