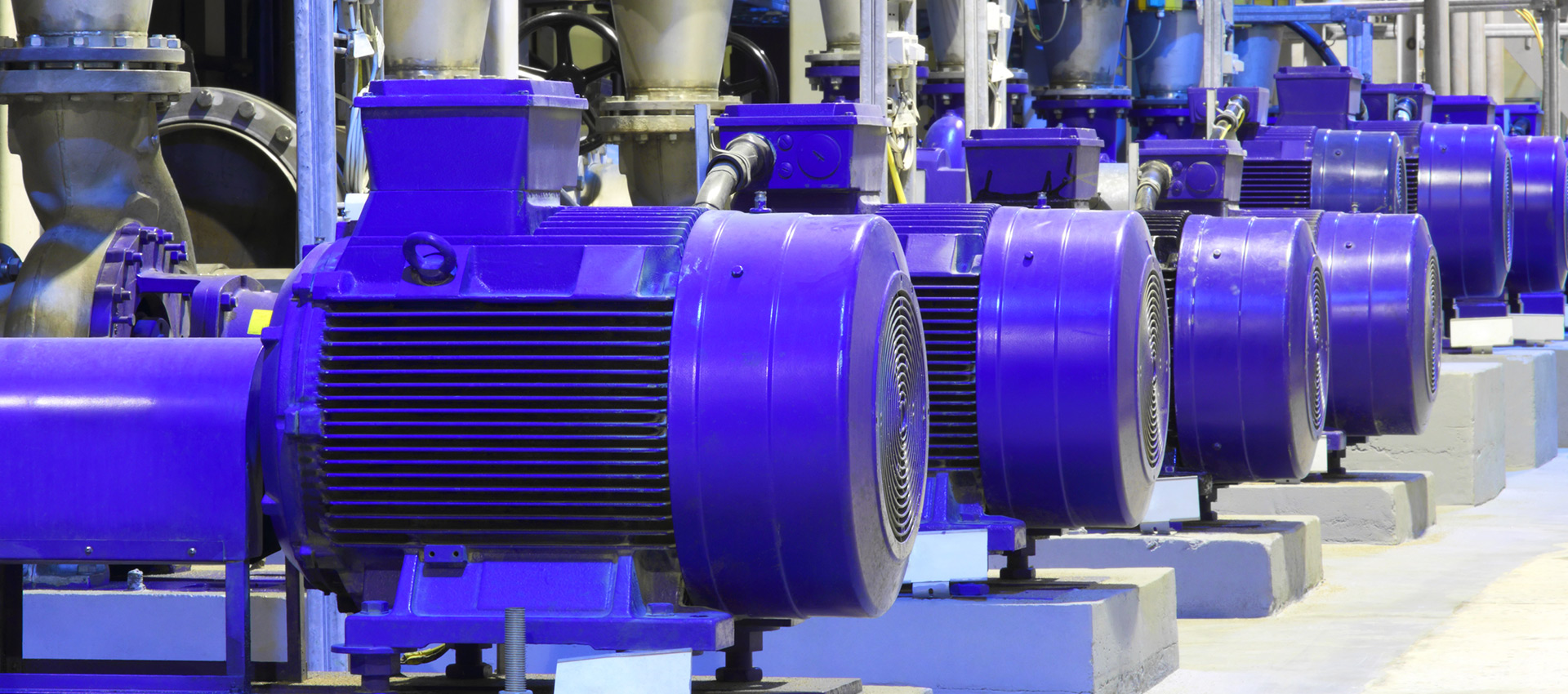

simalube for professional lubrication of electric motors

Electric motors are used to drive many devices, working machines and vehicles. Electric motors usually generate rotating movements, but they can also be built for translatory movements (linear drive). Electric motors usually have bearings on 2 sides, and these bearings must be lubricated. There are several factors that determine how often a bearing should be lubricated: Operating hours, speed, bearing size, bearing type and the way the motor is mounted are just a few of them. For this reason, simatec has developed Calculation Pro for you, which helps you choose the right lubricant dispenser for your engine.

Lubrication points

Challenges

- Environment: high temperatures, high temperature fluctuations, pollution

- Technical: high loads, vibrations, high operating temperatures

- Installation: poor accessibility, little space, sometimes increased back pressure

Solution

- In most cases, the lubricators are mounted directly on the lubrication points (bearings or seals). If the lubricant is supplied via a hose line, the IMPULSE connect, with which a higher pressure can be achieved, is often used.

Areas of application and advantages

Environments in which simalube can be used

- Industrial fans and blowers

- Conveyors

- Turbines

- HVAC

- Pumps

Advantages of the simalube lubrication system

- Reliability: Once installed, the lubrication points are reliably lubricated and never forgotten

- The hermetically sealed system prevents contamination by dust and debris (IP68)

- Reduction of service requirements and maintenance costs: Manual lubrication is no longer necessary meaning fewer disruptions and a huge saving of time

- Longer service life of machines thanks to continuous and accurate lubrication

- Flexibility: The running time is adjustable from 1–12 months

- No need to shut down the machines during maintenance

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

About the product

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.