Increased efficiency in chain lubrication: A path to sustainable maintenance

The professional lubrication and care of chains plays a decisive role in the maintenance of machines and systems. It should be possible to carry out effective chain maintenance during operation because chains usually play a central role in the production process and therefore cannot simply be switched off.

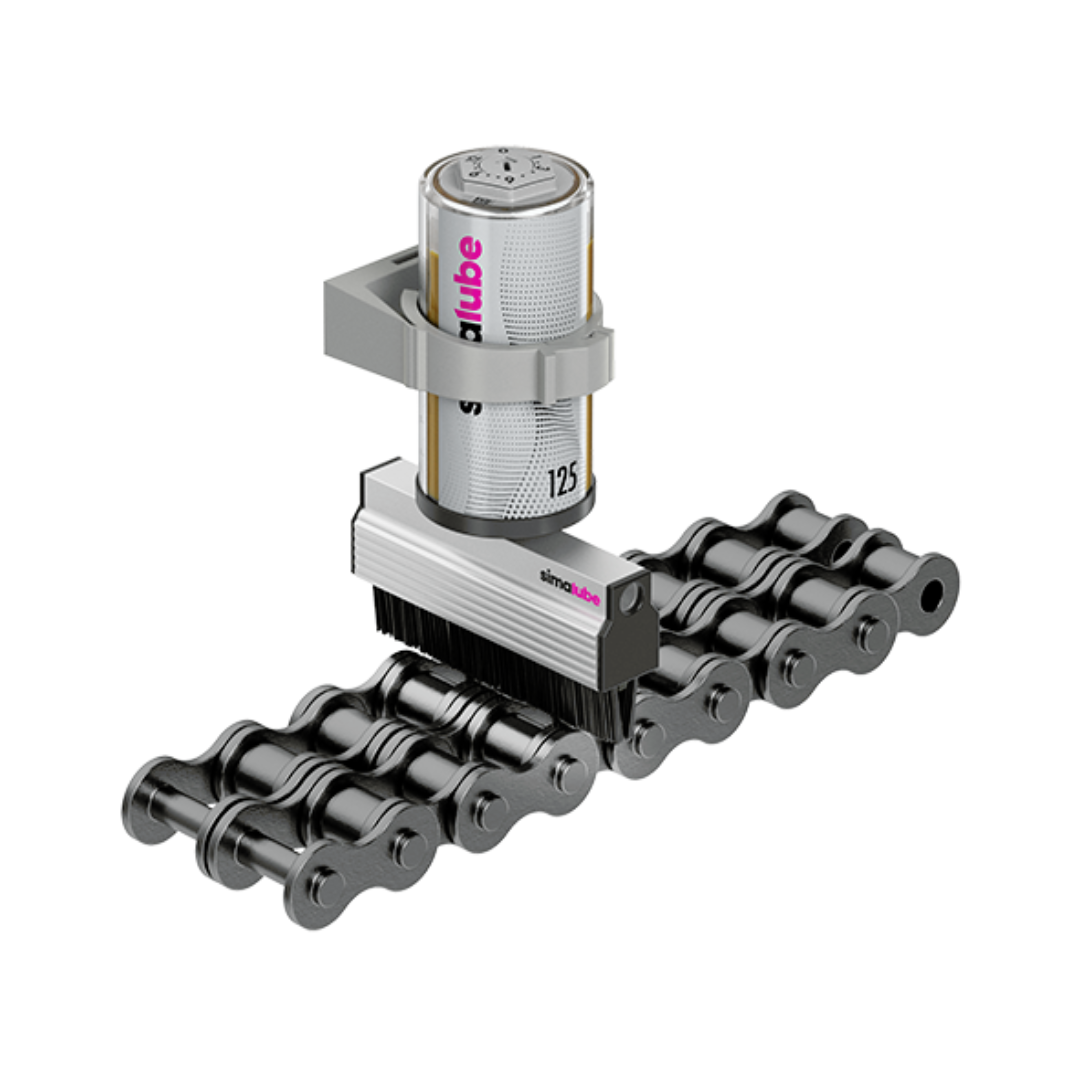

At simatec, as the world market leader for automatic lubricant dispensers, we are proud to offer innovative solutions. These go far beyond conventional maintenance methods, revolutionising the lubrication of conveyor and drive chains and contributing significantly to increased efficiency, energy savings and sustainability. In this blog post, you will learn how simalube optimises the maintenance of your chains and how this benefits your business.

Numerous advantages of automatic lubrication with simalube

Increased efficiency in maintenance

The regular and precise dispensing of lubricants is essential to extend the service life of chains and ensure smooth operation. With simalube, chains can be lubricated automatically for up to one year, eliminating the need for time-consuming manual lubrication processes and resulting in significant efficiency gains.

Reduced downtimes

Automatic lubrication means fewer interruptions for manual maintenance work. This significantly increases the availability of your systems and boosts their productivity.

Sustainability and environmental responsibility

Read more about saving CO2 and saving valuable resources on our simatec blog.

Use in various industries

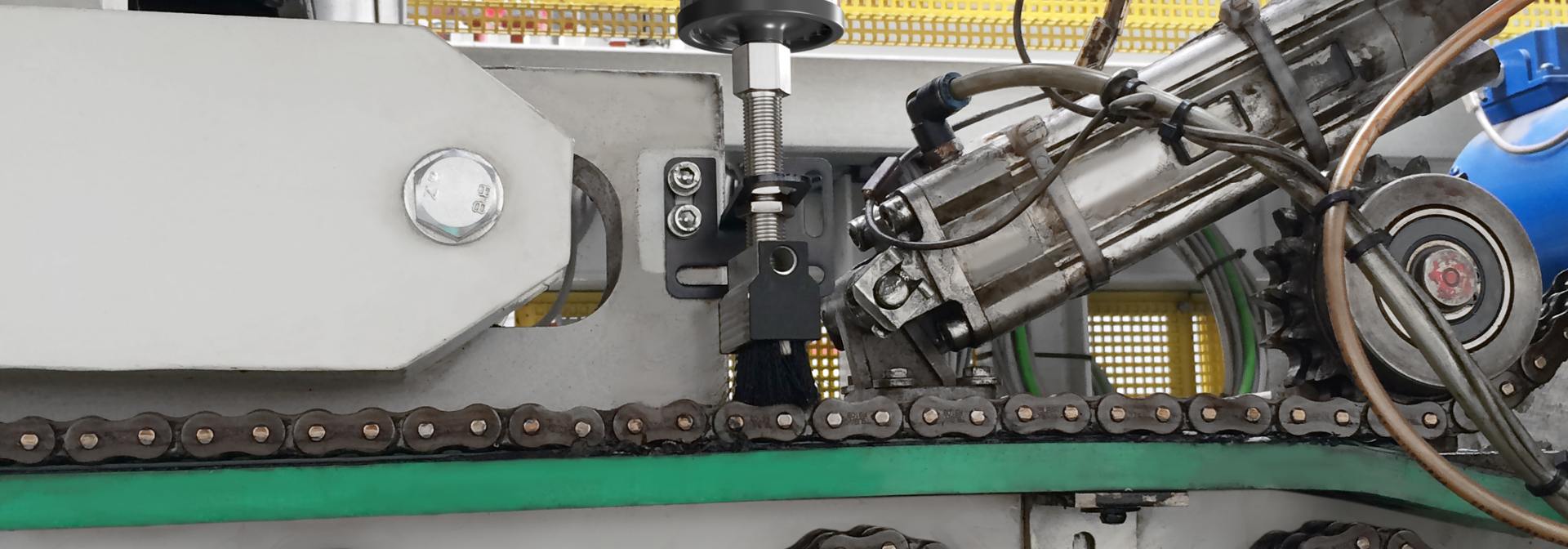

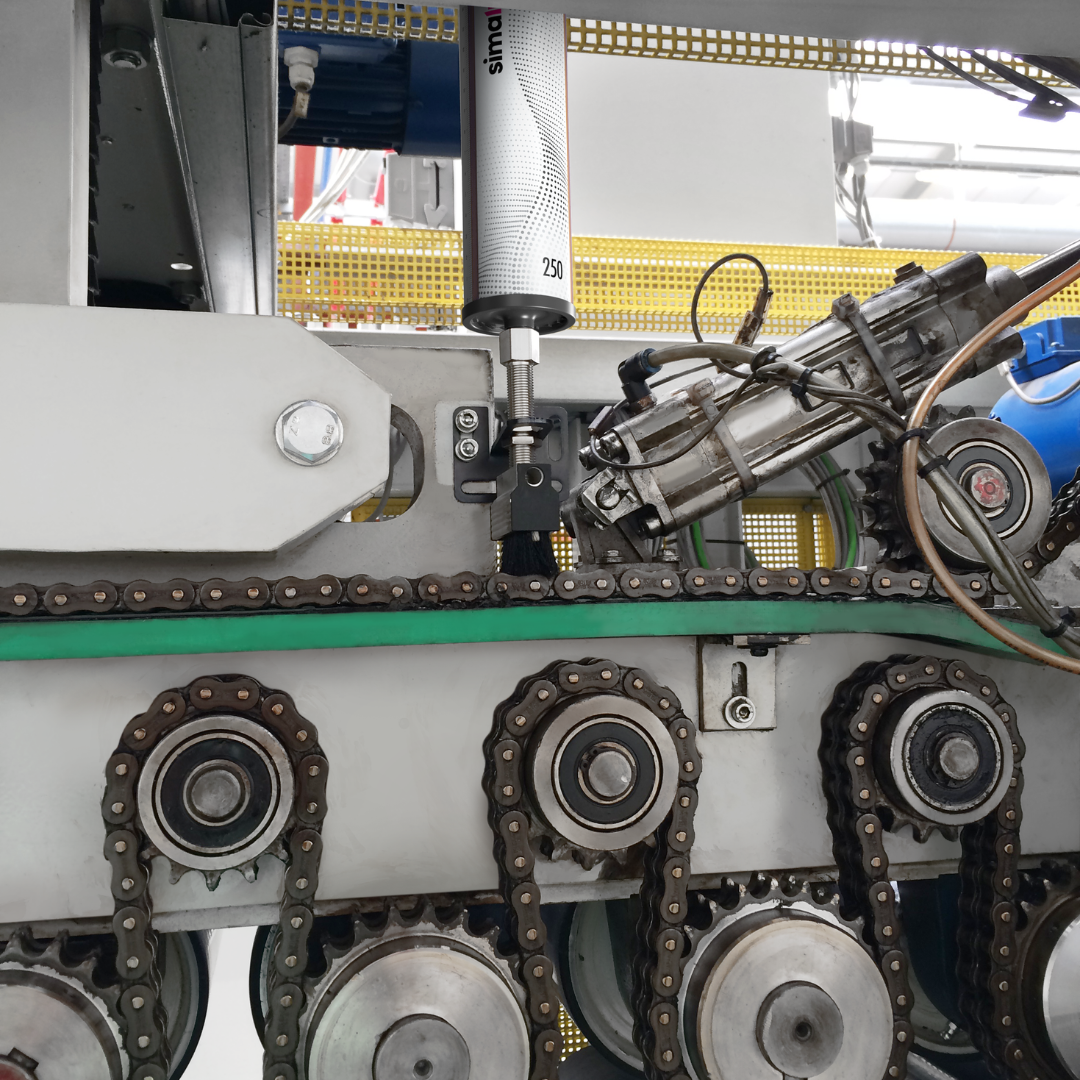

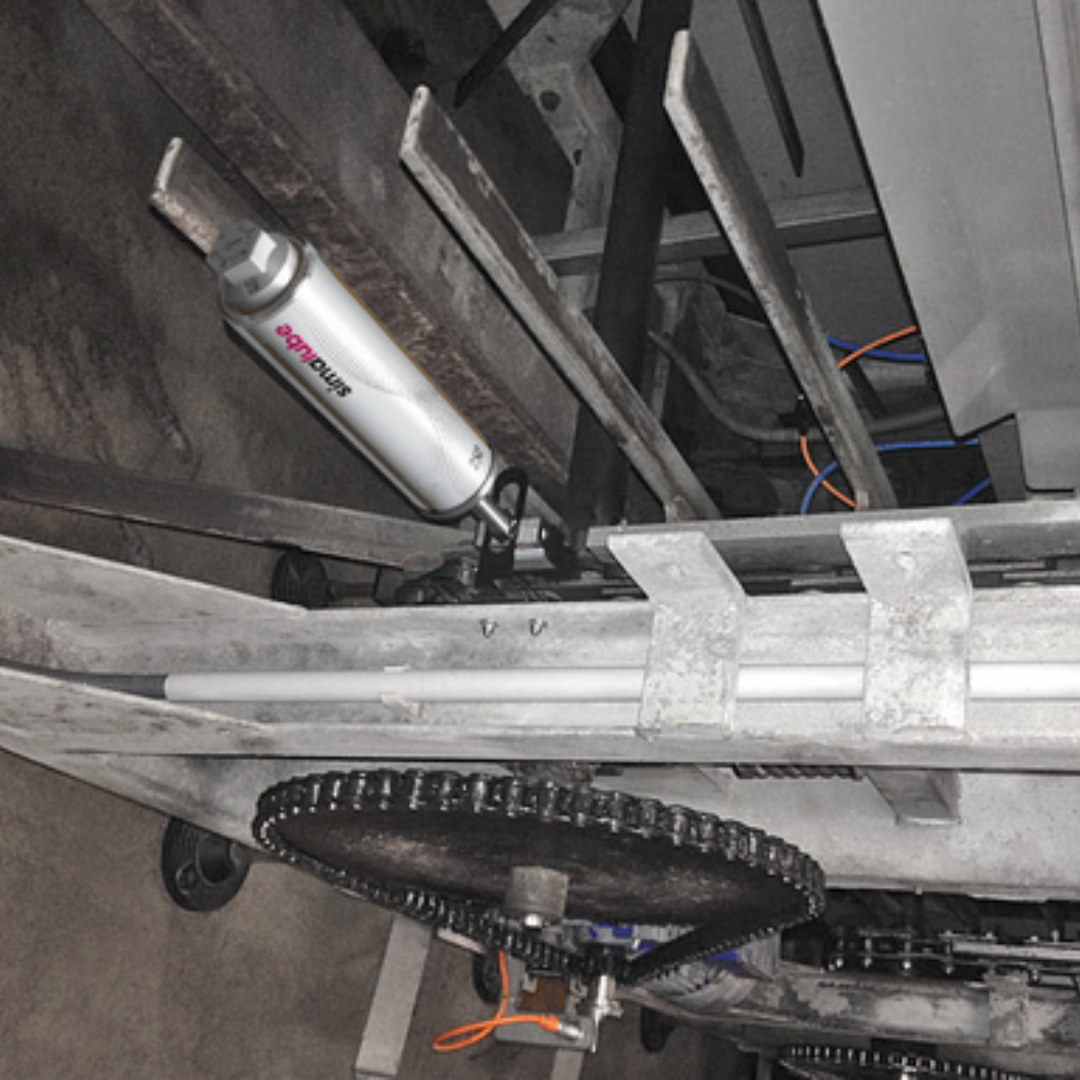

The versatility of simalube lubricant dispensers can be seen in their use across various industries. Here are some examples of where and how chains are lubricated with simalube in practice:

Production systems in the food industry

You can find a complete overview of simalube applications here: simalube applications

Take the next steps towards a successful future with simalube

The automatic lubrication of chains with simalube offers numerous advantages that go beyond simply increasing efficiency. Energy savings, sustainability and a significant reduction in downtimes make simalube an indispensable solution for modern maintenance concepts. As Head of Product Management at simatec, I invite you to find out more about our innovative products and experience the benefits of automatic lubrication in your company.

Find out more about simalube and how our products can revolutionise your maintenance processes. Visit our website simatec.com and discover how you can increase efficiency and sustainability in your business with our solutions. Contact us for a personalised consultation and let our experts support you. Together we can optimise your maintenance strategies and shape the future of maintenance.