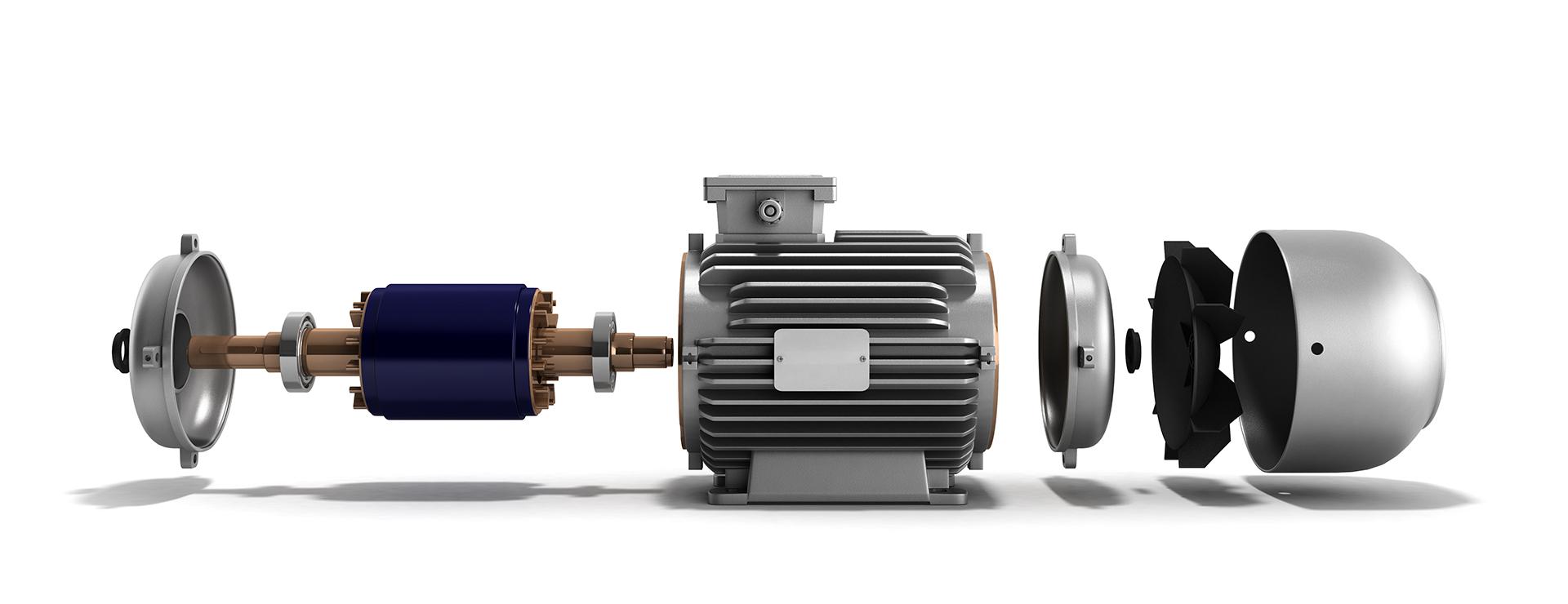

Solutions for innovative maintenance of electric motors

Using simalube lubricators significantly reduces maintenance costs of electric motors. Over 50% of electric motor failures are bearing related and the majority of those are due to improper lubrication or improper mounting. With the innovative simatool toolsets and simatherm induction heating devices, fast and safe mounting and dismounting of rolling bearings is also guaranteed.

A - Electric motor reference tag

There are several factors that determine how often a bearing of an electric motor should be lubricated: hours of operation, RPM, bearing size, bearing type and the way the motor is mounted are just a few of them. For this reason, simatec has developed Calculation Pro for you, which helps you choose the right lubricator for your motor.

B C - Non-drive end lubrication point and drive end lubrication point

The simalube automatic lubricator, available in five different sizes, supplies grease or oil to all types of lubrication points. simalube lubricators ensure a consistent supply of lubricant in the specified dosage. Downtimes are reduced and costs are significantly lowered compared to time-consuming manual lubrication. simalube lubricators can be attached to the lubrication point within seconds. The simalube is driven by a gas producing dry cell.

D - Roller bearings and radial shaft seals Dismounting with simatool

The Twin Puller TP 150 toolset enables the dismounting of deep groove ball bearings and radial shaft seals. A significant advantage is that the shaft does not have to be removed during the process.

D - Roller bearing mounting with simatool

The FT 33 mounting tool is used for the careful mounting of roller bearings and radial shaft seals.

D - Mounting roller bearings with simatherm

Inductive heating of rolling bearings and ring-shaped metal parts has proven to be a gentle and fast assembly method. An alternating magnetic field induces a high current in the workpiece in a targeted manner and brings it to the specified assembly temperature in an exact and controlled manner.

This can reduce costs and increase the service life of the engine.