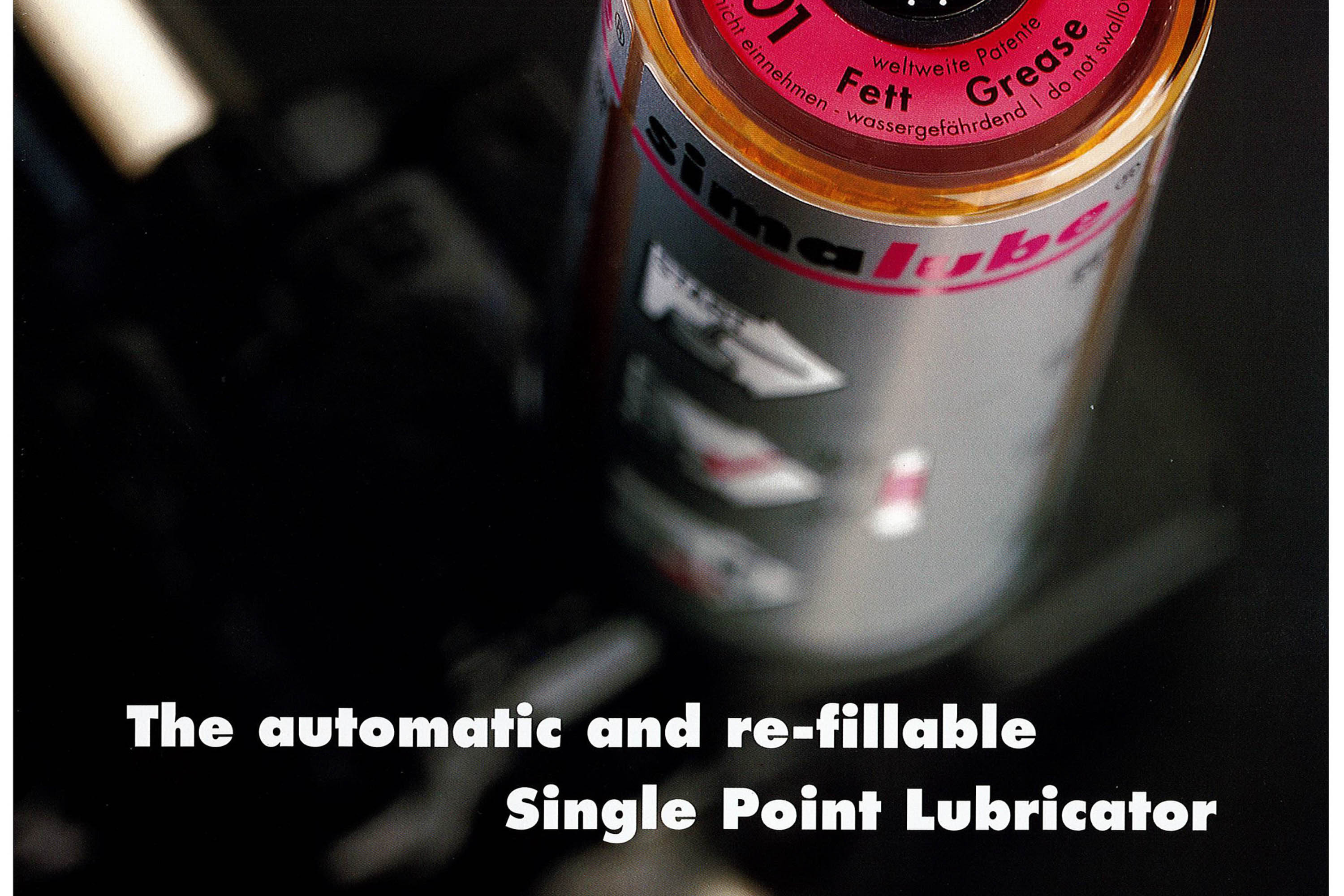

30 years of simalube: a success story in industrial lubrication

30 years ago, the introduction of the simalube lubricant dispenser set a milestone in industrial maintenance and servicing. Since then, this automatic lubricant dispenser has become an indispensable component in many industrial applications. In this article, we take a look at the history, the technical innovations and the significant benefits that simalube has brought over the last three decades.

Technological innovations and development

The simalube lubricant dispenser impresses with the following features, some of which have been unique since its launch:

- Stepless adjustment of the running times from 1 - 12 months

- Environmentally friendly and reusable, which reduces the ecological footprint

- Transparent housing thanks to which the function can be easily monitored visually

- Compact size

- Easy disposal

The advantages of simalube

The advantages of the simalube lubricant dispenser are manifold and contribute significantly to the efficiency and longevity of machines and to reducing lubrication costs. Thanks to the extremely low CO2 emissions and the reusability of the products, simalube is best in class when it comes to sustainability. The most important properties are listed here once again:

- Continuous lubrication: Ensures constant lubrication without manual intervention.

- Reduced maintenance: Less time spent on machine maintenance and inspection.

- Extended service life: Protection against wear and damage thanks to optimum lubrication.

- Increased safety: Prevention of accidents due to less manual lubrication work in hazardous areas.

- Cost savings: Savings in labor and material costs due to more efficient lubricant consumption.

Areas of application and success stories

Today, millions of people travel on escalators or in elevators that are lubricated by simalube lubricant dispensers. Wind turbines, lubricated with simalube lubricant dispensers, now supply hundreds of thousands of households with sustainably produced electricity. Do you buy food, clothes or furniture? It is highly likely that these products were handled in logistics centers where simalube products ensure smooth operation. And last but not least, state-of-the-art cars powered by batteries, in whose production processes simalube lubricant dispensers play an important role, are driving on our roads.

simatec offers customized solutions for many other applications, consisting of lubricant dispensers, high-performance lubricants and the necessary accessories.

Conclusion

Three decades after its introduction, the simalube lubricator has established itself as an indispensable tool in industrial maintenance. With continuous innovation and a strong customer focus, simatec has proven that even a component as specific as a lubricator can have a significant impact on the productivity and longevity of machines. We look forward to the next 30 years and the future developments that simatec will continue to drive forward.